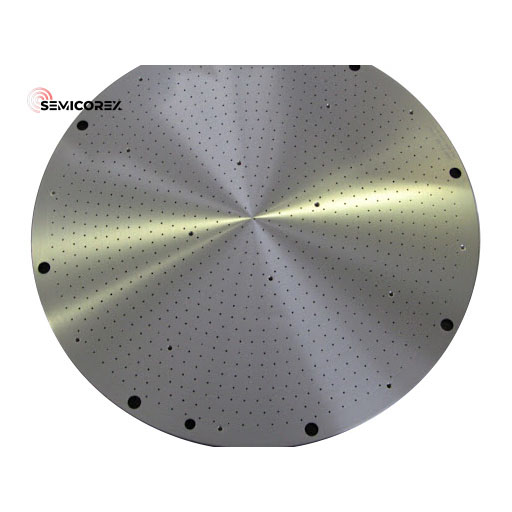

CVD-SiC Showerhead

In the context of a CVD showerhead, a CVD-SiC showerhead is typically designed to evenly distribute precursor gases over the substrate surface during the CVD process. The showerhead is usually positioned above the substrate, and the precursor gases flow through small holes or nozzles on its surface.......

Send Inquiry

Product Description

In the context of a CVD showerhead, a CVD-SiC showerhead is typically designed to evenly distribute precursor gases over the substrate surface during the CVD process. The showerhead is usually positioned above the substrate, and the precursor gases flow through small holes or nozzles on its surface.

The CVD-SiC material used in the showerhead offers several advantages. Its high thermal conductivity helps to dissipate heat generated during the CVD process, ensuring uniform temperature distribution across the substrate. Additionally, SiC's chemical stability allows it to withstand corrosive gases and harsh environments commonly encountered in CVD processes.

The design of a CVD-SiC showerhead can vary depending on the specific CVD system and process requirements. However, it typically consists of a plate or disc-shaped component with an array of precision-drilled holes or slots. The hole pattern and geometry are carefully engineered to ensure uniform gas distribution and flow rates across the substrate surface.